Food Extruders are used for converting large variety of food cereals for extruding various shapes which are pellets,

RTE Snacks, Breakfast cereals, Precooked flours and starches, Expanded products such as Soy Nuggets, Aqua feed,

and various Pasta products viz. macaroni, vermicelli, spaghetti, etc. Extruders have also been employed to produce

Soy Dal Analague product (SDAP) which taste very much like natural Tur Dal but with added proteins and nourishment

than possible with natural Tur dal alone. Further applications of Extruders have been to produce Pet/Acquatic feeds

or pellets for Race Horse, Dog food and for other pet animals. The extruded pet food not only aids in easy digestability

by the animal, but could be made with added minerals, vitamins or flavours thus providing useful ingredients and taste to

the animal promoting it’s all round growth. More Recently, Extruder has been developed for producing Fortified/Reconstituted

Rice which can produce natural Rice fortified with added minerals or vitamins which is very healthy for the consumer

Thus Food Extruders have very wide applications.

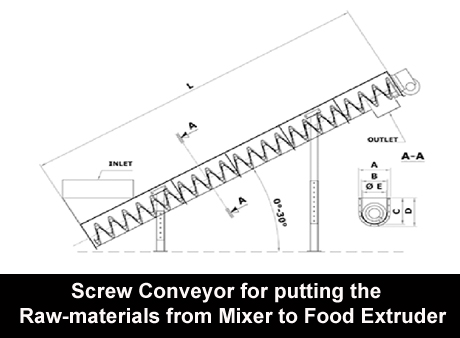

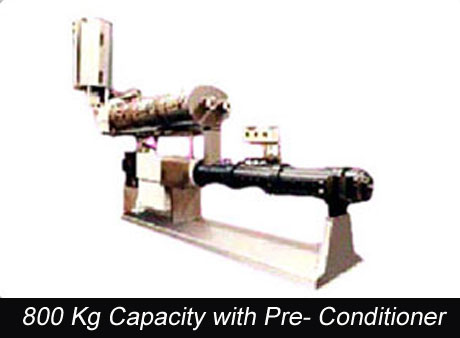

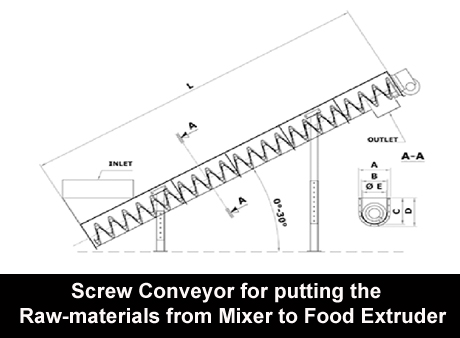

Following categories of Extruders are used for producing the above products:

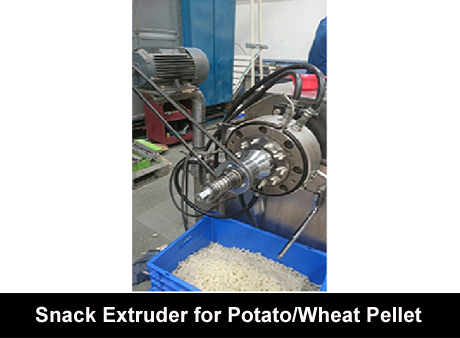

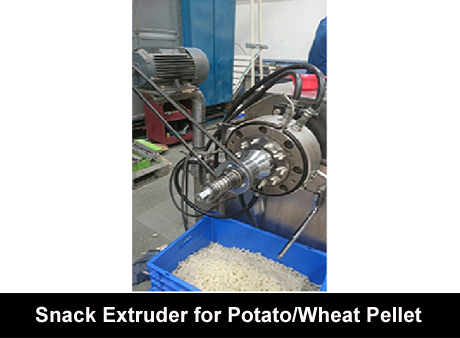

Pellets are half-cooked products or “third generation” Snacks, and need to be fried or heated in hot oil or air for

complete expansion and consumption. Raw pellets are produced using HTST and Former or Product Densification Unit

(PDU)- Raw-materials (Wheat, Rice, Potato, etc.) being first cooked, followed by cooling and densification in the Former.

The Former is fitted with various die inserts for forming the shape of pellet, e.g. Wheels, Tubes, Stars, Etc. In addition

to conventional 2-D shapes mentioned, 3-D or hollow pellets are formed using special tubular die units to extrude a cooked

sheet first with two layers. The two layers after collapsing and pre-drying could be punched with suitable dies to get 3D pellet

which are further dried before final packing.

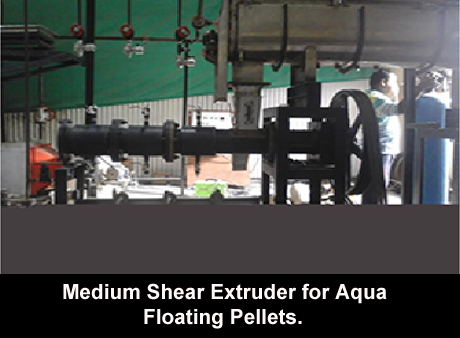

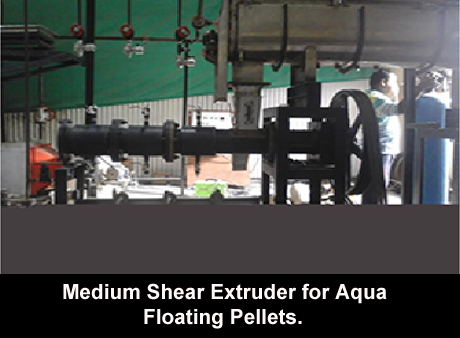

Direct Expanded Snack products are produced using High Shear Adiabatic Extruders, using various Food Cereals which are

fully expanded immediately as they emerge from the die attached to the Extruder. They are used for producing RTE Snacks,

Baked Corn Curls or Collette, Soy Nuggets, Aqua Feed (floating), etc. For producing sinking aquatic feeds, combination

of Cooker (Gelatiniser) and PDU is employed.

Low Shear Extruders or Formers are used for producing various Pasta products like Macaroni, Spaghetti, Vermicelli, etc.

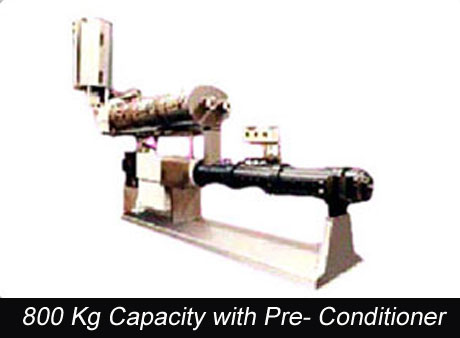

Medium Shear Extruders are employed to get partially expanded snacks, Pet foods, Snack Pellet, SDAP, Fortified Rice

and such other products needing high moisture content upto 40% approx. while processing in the Extruder.

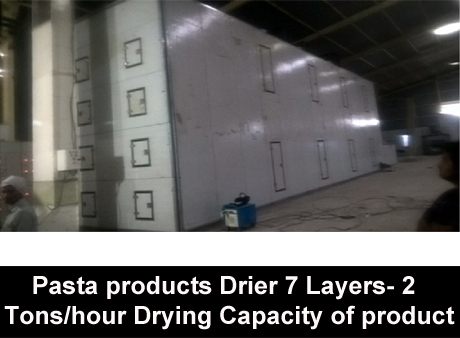

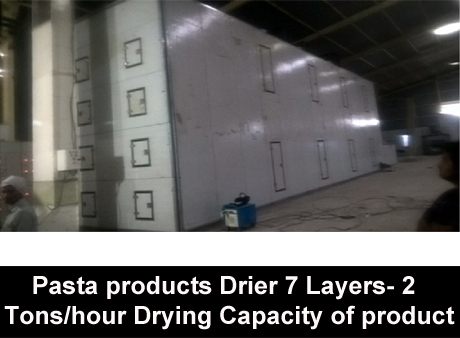

In all the above Extrusion processes, product has excess moisture and the same is removed by passing in Dryers before

the product cools down for safe packing. The Drying Equipment should include a Pre-Dryer to remove some moisture before

final Drying in the Main Dryer to permit safe handling without sticking of products. Continuous Belt Driers with Conveying

Belts arranged in multiple decks are usually employed to operate continuously.

The Fry type Collette Extruder is a specialized Extruder designed for producing Fried Corn Curls/Collette.

The working principle is entirely different from normal Screw Extruder, as the raw-material (corn meal or grits)

gets cooked between two circular bronze discs (one is fixed and other is rotating, there is no die) and randomly

cut by stationery knife on periphery. A short, feed screw feeds the de-germinated corn meal or grits between the 2

bronze discs where the material gets cooked due to high shearing forces and is cut into suitable lengths as it emerges

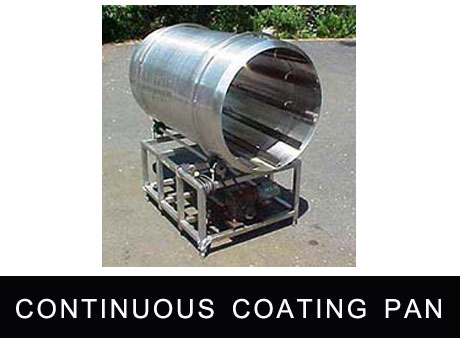

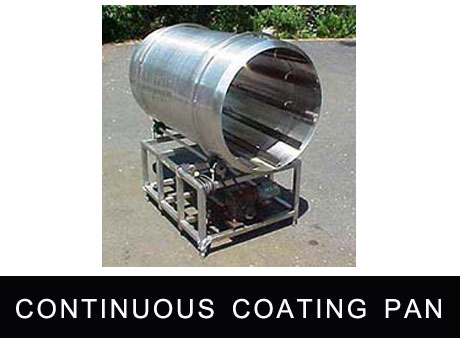

out of the gap between the discs, by the knives. The product is fried in hot oil and applied with seasonings in a coating drum.

For Range of Food Extruder being manufactured by us, download our brochure following “Download” link.